Getting the Programming from Studio to Transmitter

KYFC-

Return to the KYFC-

© 2023 Joe Snelson

KYFC-

In order to produce local television programming for KYFC-

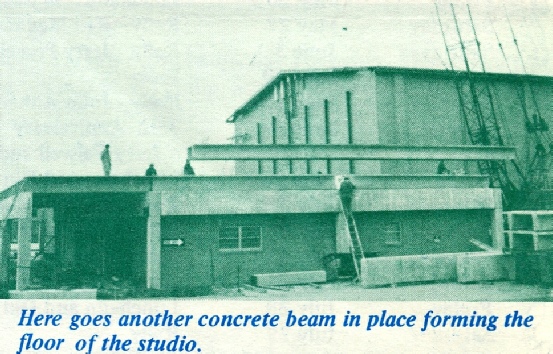

Above is the KCYFC facility. The original office building is in the foreground. The auditorium was added later. The new studio was constructed over the office building.

Inside the auditorium where the Saturday night rallies were held.

Below is a photo of the KCYFC complex showing the studio addition.

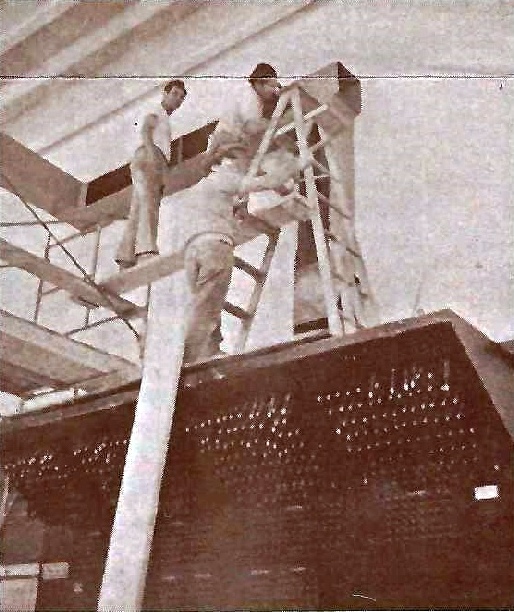

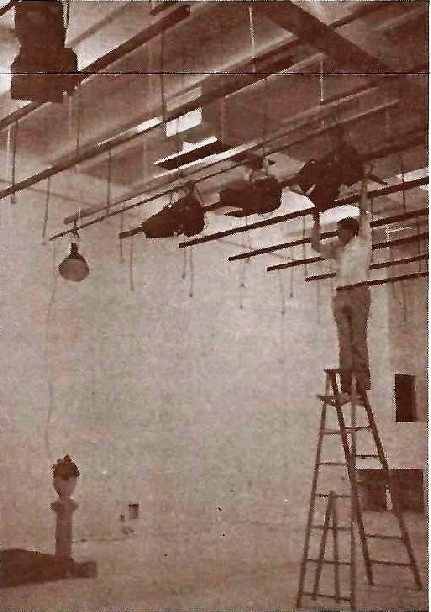

A television studio must have the capability of powering many lights that are used for a production. Most of the lights are hung on an iron pipe lighting grid that is suspended from the ceiling. Hundreds of receptacles hang from an electrical raceway attached to each pipe on the grid. The lighting grid is shown in the photo below with a light being adjusted towards a set. If you look closely you will see receptacles hanging from the grid. Each receptacle is on its own dedicated circuit so it can be independently controlled as being off, on or dimmed.

Each individual circuit terminates into the large device shown in the lower half of the photo below. This is called a lighting patch bay. It somewhat looks like an old telephone switch board. The plugs in the top of the patch bay are connected to each circuit on the grid. This makes it possible to place multiple lights on one circuit or dimmer. Each one of these plugs has a lead weight attached to it inside the panel so the cords retract when not in use. With the number of circuits available with each having a lead weight this patch bay weighs over 7,000 pounds! You can see workers preparing to run the hundreds of wires from the receptacles to the patch bay.

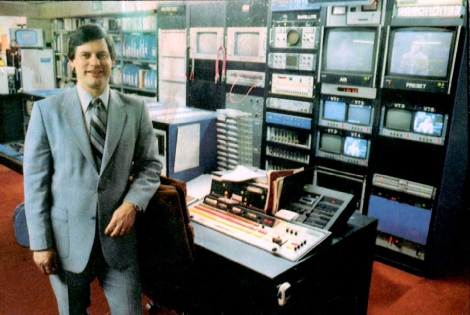

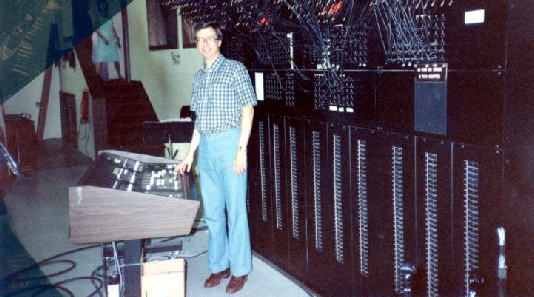

In the photo above Joe Snelson, Chief Engineer, is shown standing behind the control console that turns lights on, off or dims them. The patch bay is shown behind him. Joe recalls the challenge in getting the patch bay up to the studio. When it arrived it had been shipped on a pallet by truck. Belger Cartage was hired to do the offloading. Belger provided a fork lift to offload the patch bay from the truck to the auditorium stage door. The fork lift then lifted it up to the studio through a landing that had been constructed outside the studio and over the stage floor of the auditorium. A photo of the landing is shown on the right looking down onto the stage. The railing was removable so large items that were to big for the elevator could get to the studio.

KYFC- at the area designated as Master

Control. This is where programs are switched to go to the transmitter for airing.

Click the icon at the right to learn more about this area.

at the area designated as Master

Control. This is where programs are switched to go to the transmitter for airing.

Click the icon at the right to learn more about this area.

In the foreground is video control. The operator that sits here controls the three color studio cameras. He ensures the televised images have the correct exposure and color. For those technically inclined click the icon on the right to see the controller that is used.

Above is a photo of 3 AMPEX AVR-

Joe Snelson, Chief Engineer, is shown sitting in front of one of the machines. Judging by the manual in his lap and a telephone in the left hand he is most likely on the phone with AMPEX discussing an issue a machine is having.

Above, Joe is shown checking signal parameters on an instrument called a waveform monitor. This row of equipment racks holds the switching and electronic support gear for the station. It is sometimes referred to as the tech core. The camera control units for each of the 3 studio cameras is in the foreground. The person adjusting the cameras, called a Video Control Operator, uses the two precision color monitors in the racks to the left of Joe to visually access the picture quality and adjust the cameras as necessary.

The photos above show the studio in the full production mode. It typically took around

7 people to staff a production. This included a director, camera operators, audio

technician, video operator plus other non-

Video & Audio Control Rooms

Studio equipment selection and ordering began in late 1977. Cameras, video tape recorders,

production switcher and other equipment arrived in February, 1978. Up to now, the

KCYFC program Christ Unlimited was produced at the CBS affiliate in Kansas City,

KCMO-

Technical Center & Master Control

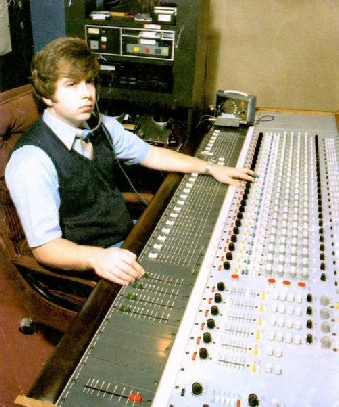

Tony Stevens is operating the Neotek audio console. To his left a cartridge tape

player is shown on top of a cabinet. This device played tapes similar to the old

car 8-

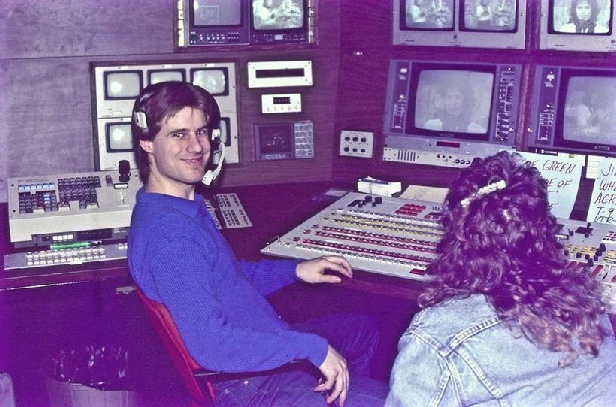

Andrew Bales is seated behind the Vital video production switcher. Note the monitors in front of him. There is a monitor for each camera and tape machine. In this photo Andrew is the Director/Technical Director and selects what camera or tape machine goes on the air or gets recorded onto videotape. He also has control of graphics and other imaging devices to his left. He directs the camera and crew on what to do using his headset.

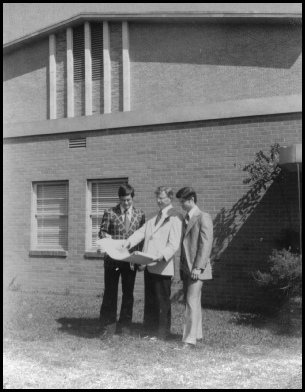

Shown above: David Lewis, Al Metsker and Ronnie Metsker are reviewing the drawings for the new studio addition

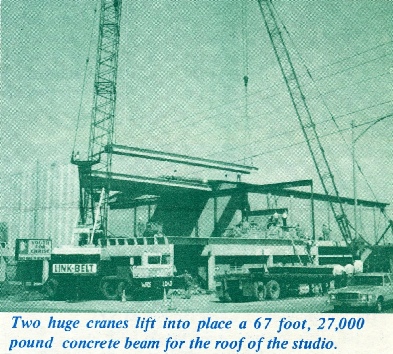

Joe Snelson shares a story that happened not long after excavation began for the

basement offices of the new studio edition. Around early September, 1977 excavation

had started for the basement area directly in front of the existing office complex.

A hole of about 10 feet deep had been dug for the new basement offices. On September

12 late afternoon I was getting ready to head home. I was talking to some people

in the KCYFC parking lot, one of whom would be my future wife. I noticed a storm

was brewing and said goodbye as I wanted get home before it cut loose. Within about

30 minutes it indeed did cut loose. I am referring to the infamous 1977 Brush Creek

Flood. As we entered the weekend I was driving by KCYFC headquarters and noticed

the front was all lit up. I wondered what was going on. When I looked closer I saw

that the entire front of the office building was gone! It had collapsed into the

hole that was dug due to the extreme rain we had that week. It had saturated the

ground and the building footings had given way. I parked my car and went inside.

We were in a damage control mode, literally. We grabbed lumber to put up temporary

shoring to keep the roof from collapsing. What we did worked. A temporary plywood

building front was constructed and held us over until the new addition was completed.

There were some close calls during construction as we would experience occasional

cave-

Studio Production

Studio Lighting

A lot of maneuvering took place but we finally got it on the landing. Next was to

get the patch bay in place. We placed the patch bay on 1-