Studio to Transmitter Link

KYFC-

In the broadcast industry this is called a Studio to Transmitter Link (STL). Located at the studio is a low power transmitter that operates in the microwave frequency band. There is a receiver at the transmitter site that receives the audio and video signals from the studio and sends them to the high power television transmitter for broadcast. The antennas used for the STL look similar to the one in the photo on the right.

These parabolic antennas, sometimes referred to as “dishes” focus the energy into a narrow beam. The dishes at both ends must be lined up precisely looking towards each other.

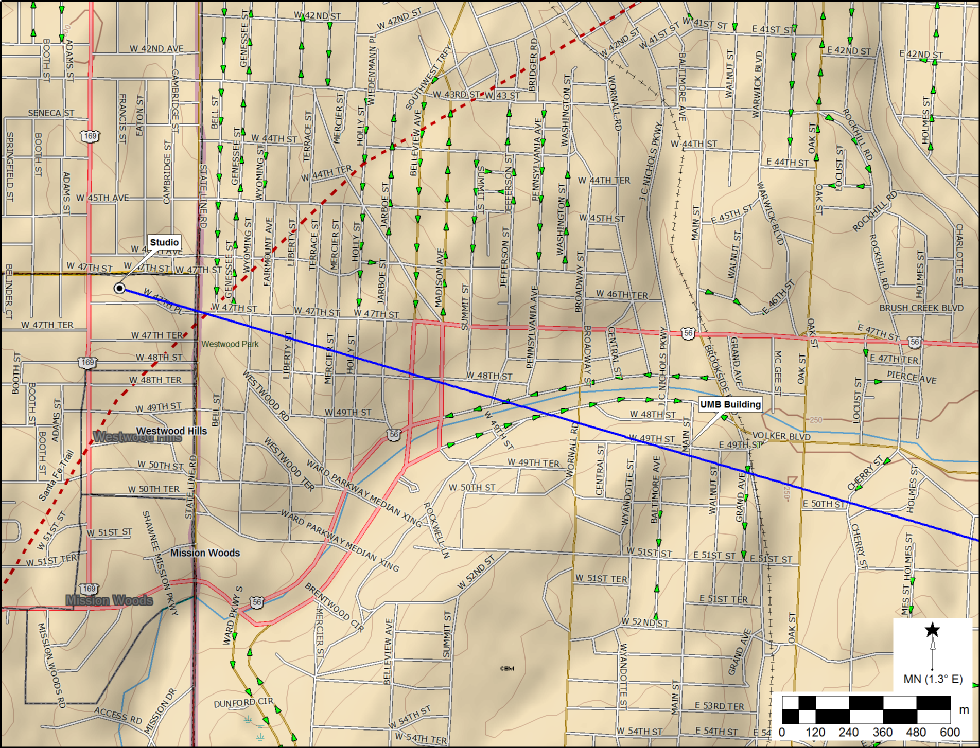

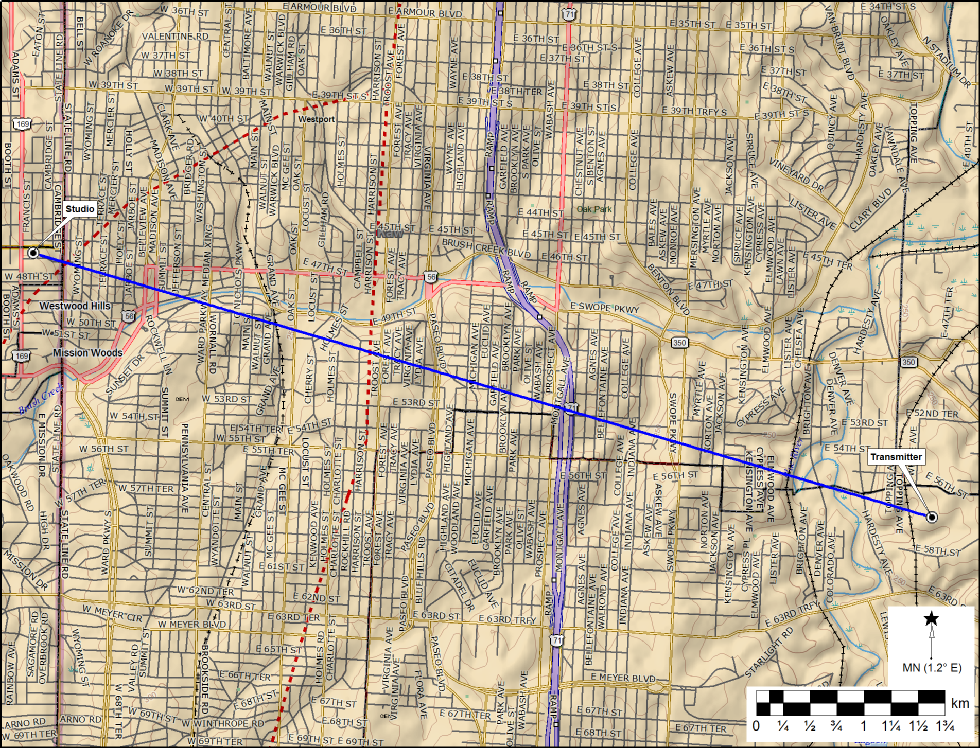

The map below shows the path of the STL. You will see the starting point at the KYFC-

The solution was obvious. We couldn’t move the building so we had to move an antenna. Moving the studio antenna was not an option as that would have required constructing a tower. That would not only be expensive but was highly unlikely of being approved by the City of Westwood.

However, the dish at the tower could be moved fairly easily. Path engineering showed that moving that antenna up another 200 foot on the tower would adequately clear the obstruction. This is what was done and everything was back to normal.

Return to the KYFC-

© 2023 Joe Snelson

As you can see, the STL is a critical component of a television station. Nowadays

many stations use fiber or even specialized Internet services to connect the studio

to the transmitter. Those options were not available back in the 70’s. Some stations,

however, continue to use microwave radio links for their primary STL or as a back-

Joe Snelson shares a second story. One day in 1987 he received a call from the then

current KYFC-

The maps and equipment mentioned above were given as background for a couple of stories

we would like to share that interrupted KYFC-

The first story was submitted by Roger Topping, a former KYFC-

After we got the line dried out as best as we could,

the tower professional did an inspection and found that two cover flanges had been

put together at the flex going to the dish. He inserted a pressure window with gaskets

to solve the issue. [The flex being referred to a short piece of very flexible wave

guide that couples the regular waveguide to the dish. There was leaking occurring

at this location. Think of it like a short hose going from your outside faucet to

a garden hose reel that has bad washers and is leaking.]

The line that is used to connect the dish to the transmitter or receiver is called waveguide. Without going into the technical reasons you can’t just use wire for equipment that operates in the microwave band. A photo of what waveguide looks like is shown on the right. It is made of copper and hollow on the inside. The corrugated copper allow it to be easily bent. It is covered with a black polyethylene jacket.